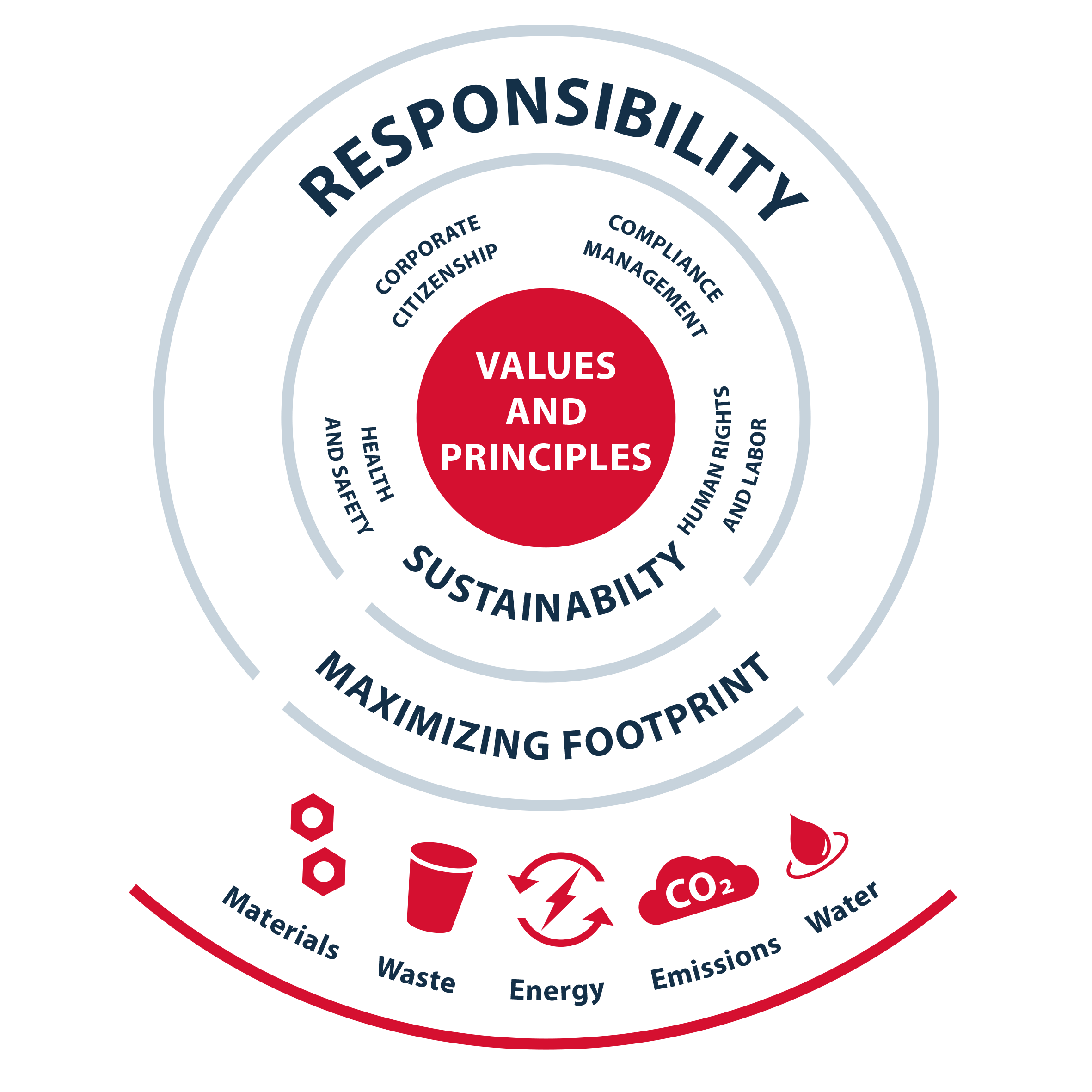

As a company that thinks in the long-term, camitec views careful resource management to keep potential environmental damage to a minimum as part of its remit of corporate responsibility.Thinking and acting in the long term are integral parts of our corporate strategy and our social responsibility.

In addition to energy savings and efficiency gains, we use sustainable production methods to leave the smallest possible ecological footprint.