MONOTUBING

As a leading manufacturer of tubing made using various types of plastics, camitec is well-positioned to fulfill the broad range of customer requirements. Regarding internal diameter and wall thickness, our tubing has tight tolerance parameters and is subject to rigorous controls during manufacturing. Our products have biomedical/pharmaceutical quality and demonstrate exceptional flow properties. Camitec precision tubing offers the highest degree of accuracy making them suitable for the most demanding of applications that requiring the highest degree of precision. The tubing is cut to length and individually packaged.

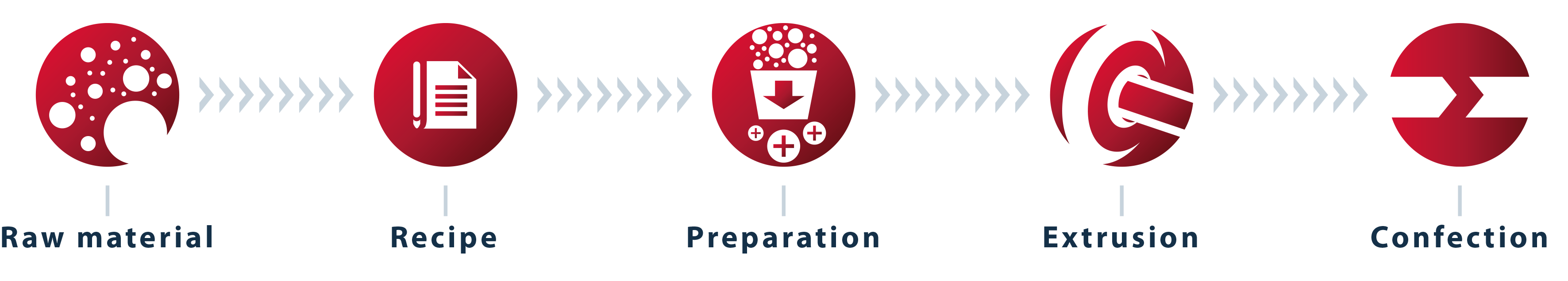

From the selection of the correct raw material to the composition of the formula, and preparation to precise production and commissioning, camitec controls and manages all processes thus guaranteeing the highest quality

FROM STANDARD THERMOPLASTICS TO HIGH-PERFORMANCE MATERIALS

When it comes to materials, we offer the full range of fluoropolymers and special plastics which have proven their effectiveness in medical devices.

Our range of materials is comprised of standard thermoplastics, such as PVC and polyolefins, as well as technical thermoplastics, such as polyamides and polyurethane. In addition, we offer silicone and high-performance materials, such as PFA, FEP, PVDF, peek, PEI and THV.

Our extruders and tools can produce tubing with diameters between 0.1 mm and 50 mm . Regarding material characteristic, measurements, and tolerance specifications, all our tubing items are custom produced in accordance with the needs of the customer.

The highest level of extrusion individuality.

With R&D engineers working on new, innovative products, we provide quick responses, technical support, and free manufacturing prototype samples. We cooperate closely with production engineers to meet or improve our goals. QA-specialists evaluate our quality systems and certified processes in accordance with USP Class VI.

We also offer the following:

- Individualized dimensions and tolerances

- Surfaces in line with customer requirements, i.e., matt, smooth, grey, glossy…

- Transparent, dyed, or contrasting tubing

- Individual packaged, wrapped, on spools, fixed lengths…