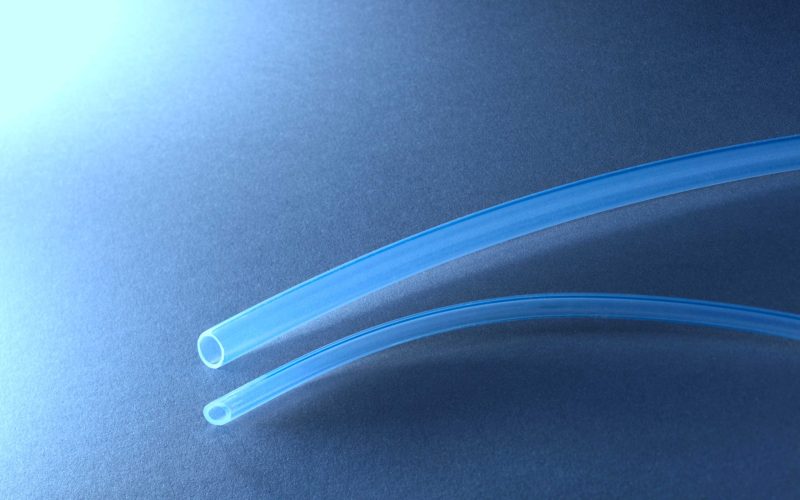

PE TUBING

For the manufacture of PE (Polyethylene) tubing, a fundamental distinction is made between two types -PF (low-density polyethylene) and HDPE (high-density polyethylene). The most notable difference between LDPE and HDPE is their flexibility. LDPE hoses are very flexible, while HDPE hoses are significantly harder and stiffer.

Raw materials

Standard types from Total, BASF, and other manufacturers.

Material information

Temperature resistant up to approx. +55°C°C depending on the type of material used.

- Milky-white coloration

- Highly diffusion-proof (excellent barrier properties)

- Good chemical resistance

- Good sliding properties

- Resistant to many acids and lyes

- Weldable

- Low weight

Areas of application

- A unique product in the field of medical technology

- Water and potable water supply

- Pressurized air applications

Standard dimensions

PE tubing is only produced for our customers in customized form. We are so convinced of the outstanding performance of our PE tubing that we are happy to manufacture it according to your specifications from a minimum quantity of 300-500 m.

CONTACT US

Our team of specialists is on hand to advise you.